Our company is engaged in the recycling of industrial waste or aluminum scrap obtained from both domestic and international suppliers. This scrap undergoes pre-melting, sorting, and cleaning processes to remove contaminants such as dust, paint, and oil, which enhances its efficiency. The removal of these substances improves the material's purity.

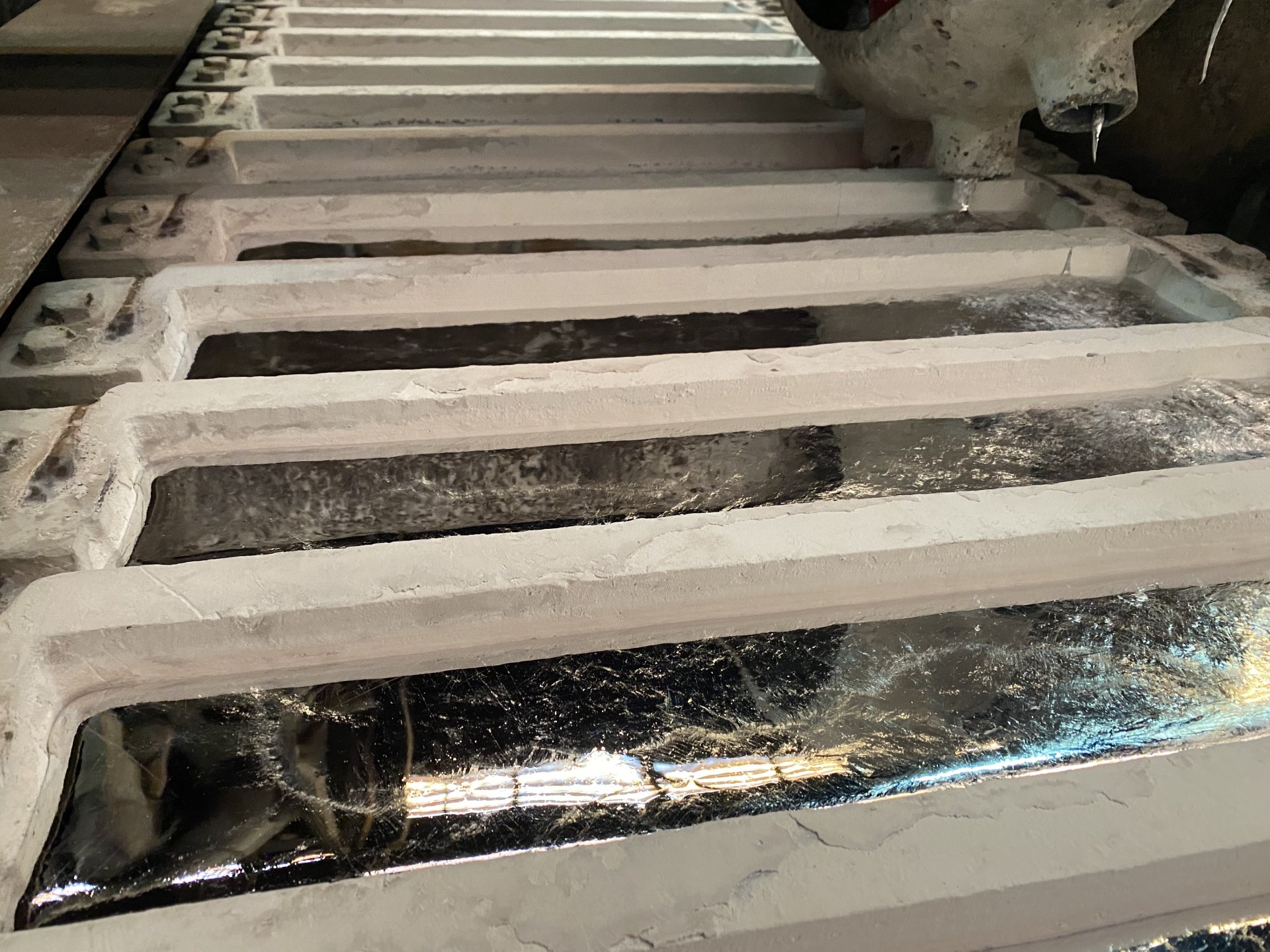

The prepared scrap is then melted in rotary, fixed, induction, and crucible furnaces. Dry filter systems are used to capture emissions, ensuring no harm to the environment. The resulting molten metal undergoes refining and degassing processes to eliminate oxides and inclusions. As a result, high-quality molten aluminum is cast into ingots through the aluminum casting process.

We are a modern manufacturing facility specializing in the production of various metals and alloys. Our production capacity and highly qualified team allow us to meet the demands of a wide range of industries, including automotive, aviation, construction, and electronics.

Our Capabilities:

- Aluminum alloys

- Copper alloys (bronze, brass)

- Stainless steels

- Ferro-titanium

- Ferro-nickel

- Alloyed steels

Induction Melting Furnace:

Our facility utilizes an induction melting furnace that provides:

- Melting temperatures up to 1800°C, enabling the processing of various metals and alloys, including aluminum, copper, steel, and titanium.

- A furnace capacity of up to 1000 kg of molten metal, allowing for the production of large volumes of alloys in a single cycle.